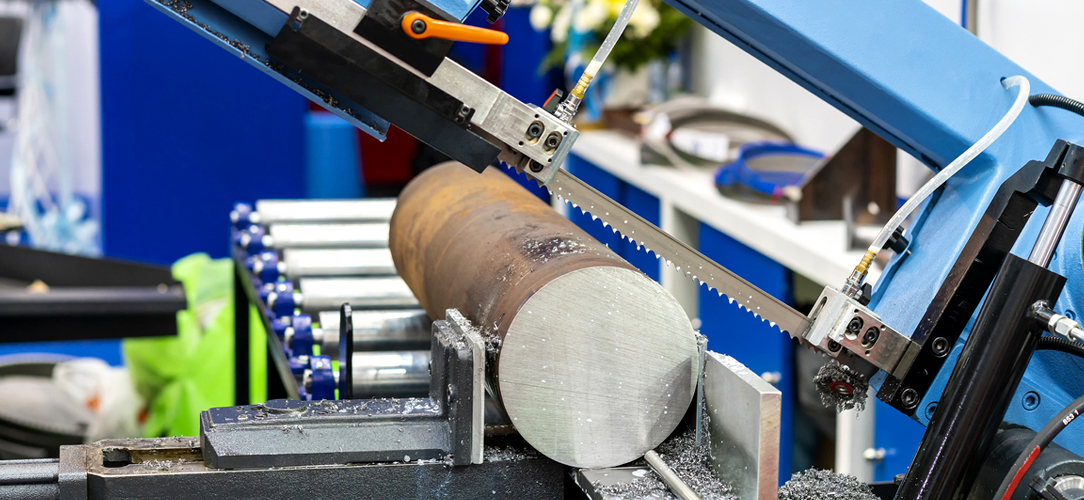

Key Safety Procedures For Using Bandsaw Machines

Operating a bandsaw can be an empowering experience. These powerful machines, often used in woodworking, metalworking, and manufacturing, are an indispensable part of many workshops around the world.

Bandsaw machines offer the ability to execute a wide range of cuts with precision and efficiency, making them a versatile tool in the hands of an experienced operator. However, it is this power and versatility that can also make bandsaw machines potentially dangerous if not handled with the appropriate respect and caution.

The combination of a rapidly moving blade, the forces exerted during cutting, and the presence of potentially unstable workpieces means that there is a significant risk of injury when using industrial level machines. However, with the correct knowledge and application of safety procedures, the risk of accidents can be substantially reduced.

In an era where sophisticated tools are becoming increasingly accessible to a wider range of users, it is more important than ever to prioritise safety in the workshop. Understanding the risks associated with bandsaw use, recognising the importance of personal protective equipment, conducting pre-operation checks, and maintaining proper body position and operational habits are just some of the ways to ensure safety when using a bandsaw machine.

Whatever your level of experience, it is vital to have a thorough understanding of the safety procedures associated with operating bandsaw machines.

Understanding Bandsaw Machines

A bandsaw machine is an exceptional piece of machinery that has revolutionised various industries such as woodworking, metalworking, and even meat cutting. Understanding the intricacies of a bandsaw machine, its individual components and their functions, is crucial for safe and efficient operation.

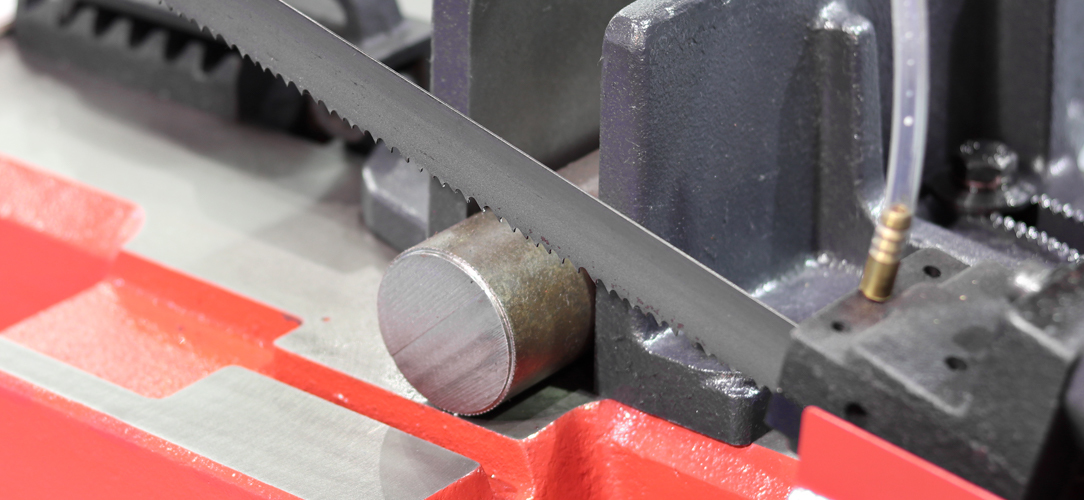

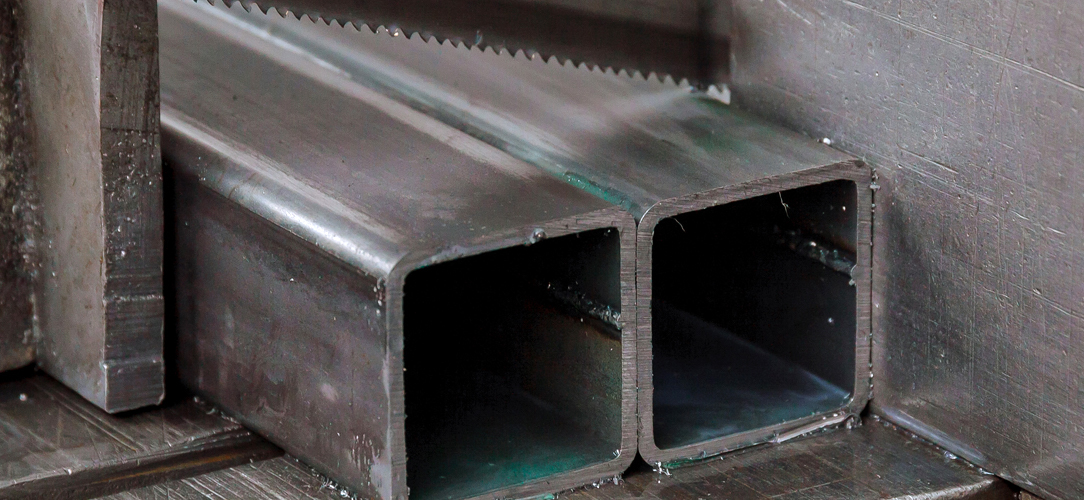

At its core, a bandsaw machine is a power tool that utilises a long, thin blade, consisting of a continuous band of toothed metal that is looped around two or more wheels. The blade's teeth vary in size and spacing, depending on the type of cut they are designed to make and the material they are meant to cut. The design of the blade allows for uniform cutting action due to evenly distributed tooth load.

The machine itself is typically made up of a frame, a pair of wheels (upper and lower), a table to support the workpiece, and the bandsaw blade. One of the wheels is driven by a motor, and this movement is transferred to the blade. This motorised wheel is also called the drive wheel. The second wheel, or the idler wheel, is used to guide and tension the blade.

The table, usually made of cast iron for durability and stability, provides a firm surface for the material or workpiece. It often includes a slot through which the blade passes, and a guide or fence that helps ensure straight cuts. Some bandsaw tables can tilt for making angle cuts.

The blade guides and guard, located above and below the table, help to keep the blade aligned and minimise deflection, ensuring a straight and safe cut. The guides can usually be adjusted to the thickness of the material, and the guard should always be positioned just above the workpiece to protect the operator from the blade.

To ensure optimal performance and safety, bandsaw machines often include features to adjust the blade tension and tracking. Tension must be adjusted when changing the blade or making different types of cuts, while tracking adjustments ensure the blade stays on the wheels' centre.

Pre-Operation Safety Checks

Before engaging with the bandsaw machine and starting any cutting work, a series of pre-operation safety checks are crucial. These checks act as a first line of defence against potential mishaps and are vital in ensuring that the machine is in a safe and proper condition for use.

Inspection For Visible Damages

Before operating, visually inspect the bandsaw machine thoroughly. Look for any signs of damage to the frame, table, wheels, blade guides, or any other part. A machine with damaged or malfunctioning parts can be unsafe to use and could potentially cause an accident. Look for any signs of wear, such as cracks, dents, or any parts that are loose, missing, or out of alignment.

Blade Tension & Tracking

The tension of bandsaw blades is crucial for accurate and safe cutting. If the tension is too low, the blade may wander or slip off the wheels, leading to an uneven cut or potential injury. If the tension is too high, it can cause undue stress on the blade, leading to premature wear or breakage.

Each bandsaw machine has a tensioning device, often a knob or a lever, that allows the operator to increase or decrease the tension. It's important to refer to the manufacturer's guidelines to understand the correct tension for your specific machine and the blade you're using.

Alongside tension, tracking adjustment ensures the blade stays on the wheels' centre. A misaligned blade could run off the wheel or twist during operation, posing a safety risk.

Blade Guards Adjustment

Blade guards are critical safety components of the bandsaw machine. They protect the operator from the moving blade and reduce the risk of accidental contact. It's crucial to adjust the blade guard for the thickness of the material you're cutting. As a rule, the guard should be positioned about 1/4 inch above the workpiece. This minimises the exposed blade length, thereby reducing the risk of injury.

Checking The Work Area

Beyond the machine itself, it's important to consider the safety of your workspace. Make sure the area around the bandsaw is clean, uncluttered, and well-lit. Remove any tripping hazards or objects that could interfere with your ability to operate the machine safely.

Safe Bandsaw Operating Procedures

Operating a bandsaw machine can be a complex task that requires careful attention to detail and adherence to specific guidelines to ensure the operator's safety.

Correct Body Position

The operator's body position is integral to the safe operation of a bandsaw. Standing in a balanced, stable position is important to maintain control over the machine and the workpiece. Feet should be positioned shoulder-width apart, providing a solid base of support.

Additionally, maintaining good posture, with a straight back and relaxed shoulders, can help avoid fatigue during extended periods of use. Avoid leaning over the machine excessively; overreaching can compromise balance and control, increasing the risk of mishaps. Instead, move around the machine when necessary, always maintaining control and a clear line of sight to the cutting area.

Safe Distance From The Blade

An essential safety rule when operating a bandsaw machine is to always keep your hands a safe distance from the blade. Even when it might seem safe, direct hand contact with the blade should be avoided. As a rule, a few inches should be maintained between your hands and the blade when feeding the workpiece.

A good practice is to use the "three-finger rule" where you avoid placing any part of your hands closer to the blade than the width of three fingers. This way, you maintain a safe distance from the blade, reducing the risk of accidental contact.

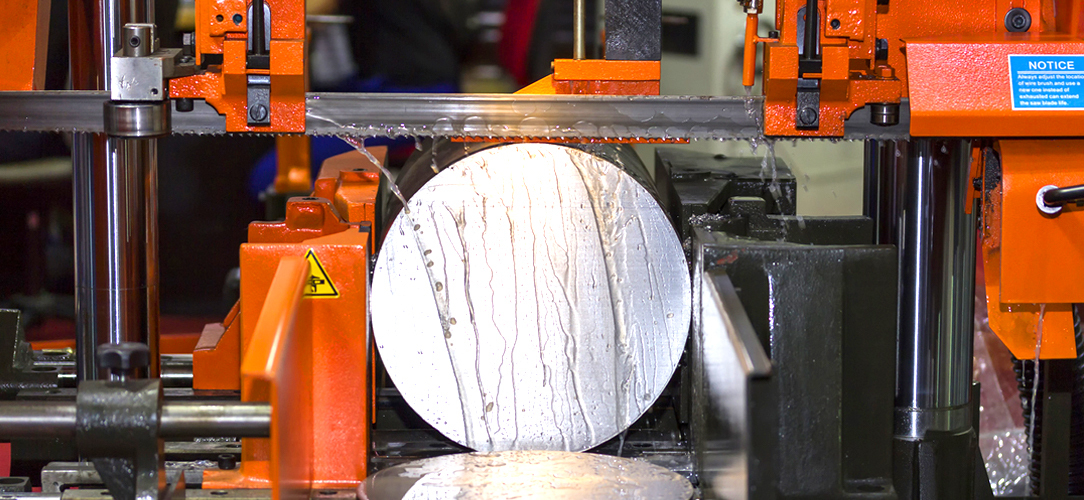

Speed Adjustments Based On Material

The speed of the bandsaw needs to be adjusted according to the type and hardness of the material being cut. As a general rule, harder materials require slower speeds, while softer materials can be cut at higher speeds.

Knowing how to adjust the bandsaw's speed is crucial for both the quality of the cut and the safety of the operator. The manufacturer's manual usually provides guidelines for speed settings, but experience and understanding of the machine's response also play a role in making appropriate adjustments.

Use Of Safety Accessories

Using safety accessories like push sticks, feather boards, and mitre gauges can significantly increase the safety level when operating a bandsaw. These accessories help keep your hands a safe distance from the blade and give you better control over the workpiece.

Push sticks and feather boards are especially useful when cutting small or narrow workpieces that would otherwise place your fingers too close to the blade. Mitre gauges help ensure precise angle cuts, improving accuracy and reducing the risk of kickback.

The Importance Of Personal Protective Equipment (PPE) When Operating Bandsaws

Personal Protective Equipment, often abbreviated to PPE, is a fundamental aspect of safety in any workshop setting, especially when operating power tools like a bandsaw machine. PPE serves as a critical last line of defence against potential injuries, providing a barrier between the user and the various hazards present in the workplace. While operating procedures and safety checks are necessary, PPE adds an additional level of protection that should not be overlooked.

Eye Protection

Among the first pieces of PPE to consider are safety glasses or goggles. Bandsaw operation can lead to the projection of small particles, dust, or even broken blade fragments, any of which can cause serious eye injury. Safety glasses or goggles should be worn at all times during bandsaw operation, even if other safety measures, such as dust extraction systems or machine guards, are in place.

Hearing Protection

Bandsaws, especially when cutting certain materials, can generate high noise levels. Prolonged exposure to such noise can lead to hearing damage over time. Therefore, the use of appropriate hearing protection, such as earmuffs or earplugs, is highly recommended, especially during long periods of operation.

Respiratory Protection

When cutting materials, especially wood, bandsaws can generate dust. Some wood species, along with certain types of treated materials, can produce dust that is harmful when inhaled. A good dust extraction system will significantly reduce the amount of airborne dust, but for an added level of protection, particularly in less well-ventilated areas, the use of a dust mask or respirator is recommended.

Hand & Body Protection

While gloves can help protect against splinters and rough material, they are not typically recommended when operating a bandsaw, as they can get caught in the blade. Instead, ensure that hands are clean and free from oils or other substances that could affect grip.For body protection, avoid loose clothing or any accessories that could get caught in the machine. Long hair should be tied back, and you should use a dust coat or apron to protect against dust and debris.

For Expert Advice

Safety Procedures For Specific Bandsaw Cutting Techniques

Operating a bandsaw involves different cutting techniques, each with its own set of safety procedures to ensure a secure operation. These techniques may vary based on the nature of the cut and the type of material.

Re-Sawing

Re-sawing is the process of cutting a workpiece along its width, creating thinner slices of the same length and width. When re-sawing, it's essential to secure the workpiece properly and adjust the blade guide and guard to the correct height above the material.

The guard should be set just above the workpiece, reducing the amount of exposed blade. Make sure the fence is parallel to the blade to ensure a straight cut and to prevent the workpiece from binding between the blade and fence. Feeding should be slow and steady to avoid putting unnecessary strain on the blade.

Crosscutting

Crosscutting is cutting across the grain of the workpiece. When performing crosscuts, it's important to use a mitre gauge or crosscut sled. These accessories help keep the workpiece steady during the cut and prevent your hands from getting too close to the blade.

It is essential that you never freehand a crosscut, as it increases the risk of kickback or the workpiece binding against the blade. Keep the workpiece flat on the table and against the mitre gauge or sled throughout the entire cut.

Curve Cutting

Curve cutting requires making cuts along a marked line on the workpiece, which is often curved. When making curve cuts, it's essential to make relief cuts first. These are straight cuts made into the waste material up to the marked line that relieve the stress on the blade during the curve cut and prevent binding.

As with other cutting techniques, it's important to maintain a slow, controlled feed rate, especially when cutting tight curves. This allows the blade to remove the material efficiently and reduces the risk of the blade twisting or breaking.

Bandsaw Machine Maintenance & Safety

Proper maintenance of a bandsaw machine is not just beneficial for the machine's performance and longevity but is also a critical aspect of operating safety. Regular care and attention can help prevent accidents caused by the malfunction or failure of machine components.

Cleaning The Bandsaw Machine

Regular cleaning is essential to keep your bandsaw machine in good working order. Buildup of sawdust and debris can affect the machine's performance and potentially create a fire hazard. After each use, remove any accumulated dust and debris from the table, blade guides, and other machine parts.

For the bandsaw blade, use a stiff brush to clean between the teeth, removing any stuck material that could affect cutting performance or cause the blade to overheat. Occasionally, it may be necessary to remove the blade for a more thorough cleaning or to access other parts of the machine.

Lubrication

Certain parts of the bandsaw machine require regular lubrication to function smoothly. This can include the blade guide assembly, wheel bearings, and other moving parts. Regular lubrication reduces friction, preventing excessive wear and potential overheating.

Always refer to the manufacturer's manual to identify which parts require lubrication and the recommended type of lubricant. Remember to turn off and unplug the machine before performing any maintenance tasks.

Blade Inspection & Replacement

The bandsaw blade is a critical component that needs regular attention. Check the blade regularly for signs of wear, such as dull teeth or cracks. A dull blade can strain the motor, overheat, or produce poor quality cuts, while a cracked blade can break during use, presenting a significant safety hazard.

Blade tension also needs regular checking and adjustment. An improperly tensioned blade can lead to inaccurate cuts or may come off the wheels. Be aware that tension requirements may vary with different blade widths or types, so refer to the manufacturer's guidelines.

Remember to replace the blade promptly when needed. When changing the blade, ensure the machine is unplugged, follow the manufacturer's instructions, and take care to handle the blade safely.

Checking & Adjusting The Guides

The blade guides and thrust bearings keep the blade aligned during cutting, preventing it from twisting or deflecting. Over time, these guides can wear or shift out of position and will need to be adjusted.

Regular maintenance is a cornerstone of bandsaw safety- by keeping the machine clean, well-lubricated, and in good repair, many potential hazards can be avoided. A well-maintained bandsaw is not only more enjoyable to use but also safer. A bit of preventive care can save a lot of problems down the line and help ensure a long and productive life for your bandsaw machine.

Why You Should Service Your Bandsaw Machine

The In-Depth Inspection

Professional servicing often starts with a comprehensive inspection of the bandsaw machine. This goes beyond regular checks performed by the operator and involves a meticulous examination of all parts of the machine. Trained service professionals can spot early signs of wear and tear or damage that could potentially go unnoticed by an untrained eye. Early detection of issues can prevent more significant problems down the line.

Detailed Component Check & Replacement

During servicing, the technician not only inspects but also cleans, adjusts, and lubricates various components of the machine. Components like the blade, bearings, motor, and other parts are checked for their condition. Worn out or damaged parts can be replaced during servicing before they cause issues in operation.

Calibration & Alignment

Proper alignment and calibration of various components are vital for the bandsaw's performance and safety. Misalignment can cause problems ranging from inaccurate cuts to increased wear and tear or even accidents. During servicing, professionals can check and correct the alignment of the blade, wheels, and guides, as well as calibrate any measurement scales and adjust blade tension and tracking.

Overall Safety Check

A significant part of professional servicing is a complete safety check. This includes checking all safety features like blade guards, safety switches, and emergency stops to ensure they're functioning correctly. Any issues can be rectified to ensure the bandsaw is safe to operate.

Advice & Guidance

Professional servicing also provides an opportunity to get expert advice on maintaining and operating your bandsaw machine. Technicians can provide tips tailored to your specific machine and usage patterns, helping you get the best performance and longevity from your bandsaw.

At Saws UK, our expert bandsaw servicing solutions help maintain your bandsaw machine in top condition, ensuring both its performance and your safety. Regular professional servicing, in conjunction with good daily maintenance practices, can greatly extend the life of your bandsaw and make it safer and more efficient to use. Remember, prevention is better than cure, and this holds particularly true for the care and servicing of your bandsaw machine.

For Expert Advice

Why Bandsaw Training Is Key

In the realm of bandsaw operation, nothing quite compares to the importance of proper training. While the machine's user manual provides a wealth of information, hands-on bandsaw training offers a deeper understanding of the bandsaw's capabilities, potential risks, and the best practices for its operation. Training is not merely a formality but a fundamental step in ensuring the safe and efficient use of the bandsaw machine.

Understanding The Machine

Bandsaw training begins with a thorough familiarisation with the machine. This includes understanding the purpose and operation of each component, the correct installation and adjustment of the blade, the function of various controls, and the signs of potential issues. A trainee learns not only what the machine does but also why and how it does it.

Learning Safe Operating Procedures

A key aspect of bandsaw training is learning and practising safe operating procedures. This goes beyond just knowing the procedures and includes understanding why each step is necessary and the risks involved if steps are skipped or done incorrectly. Trainees learn the correct stance and hand positions, the safe use of accessories, and the importance of pre-operation checks.

Gaining Hands-On Experience

Bandsaw training provides invaluable hands-on experience. Under the guidance of a knowledgeable instructor, trainees learn to make various types of cuts, adjust the machine for different materials, and troubleshoot common issues. This practical experience builds confidence and competence, preparing the trainee for safe and effective bandsaw operation.

Personal Protective Equipment (PPE) Training

Understanding and using the correct personal protective equipment (PPE) is an essential part of bandsaw safety. Training provides information on the types of PPE required for bandsaw operation, the correct use and maintenance of PPE, and the specific protection each piece offers.

Maintaining The Machine

Training also covers the proper maintenance of the bandsaw machine. Regular maintenance helps keep the machine in top condition, but it also plays a significant role in safety. Trainees learn to clean, lubricate, and adjust the machine, as well as how to inspect the blade and other components for wear or damage.

At Saws UK, we believe that comprehensive bandsaw training is an investment in safety. Our bandsaw training programs cover everything from basic operation and safety procedures to advanced cutting techniques and troubleshooting. Our aim is to ensure that every bandsaw operator has the knowledge and skills necessary to use the machine safely and effectively.

FAQs About Bandsaw Safety

Q: What To Check Before Using A Bandsaw Machine?

Before using a bandsaw machine, a series of pre-operation safety checks should be performed. Start by inspecting the machine for visible damages such as cracks, misalignment, or wear and tear. Check the condition and tension of the blade, ensuring it's suitable for the material you're about to cut.

Adjust the blade guard to the thickness of the material, keeping it as low as possible over the material. Check the table and all guides for stability and alignment.

Also, verify the condition and functionality of safety devices like emergency stops or safety switches. Lastly, ensure your workspace is clean, well-lit, and free of any obstacles or tripping hazards.

Q: What Position Should My Hands Be In When Using A Bandsaw Machine?

When using a bandsaw machine, your hands should never be in the path of the blade. Keep your hands on either side of the line of cut and maintain a safe distance from the blade at all times.

A good practice is to use the "three-finger rule", keeping your hands at least the width of three fingers away from the blade. When cutting small or narrow pieces, use push sticks or other safety devices to maintain this distance. Always have a firm but relaxed grip on the workpiece, controlling its movement without forcing it into the blade.

Q: Do You Need Gloves For Using A Bandsaw Machine?

While gloves can protect from splinters when handling material, they are not typically recommended when operating the bandsaw. Gloves can reduce the sensitivity of your touch and may get caught in the blade, increasing the risk of injury. Instead, ensure your hands are clean, free of any oils or substances, and maintain a firm grip on the workpiece. If necessary, use a push stick or other safety tools to help guide the workpiece while keeping your hands a safe distance from the blade.

A Full Range Of Bandsaw Solutions

For over thirty years, Saws UK has been a leading supplier of bandsaws and cutting machines to UK businesses. Our expertise and experience means we’re able to offer a comprehensive range of bandsaw solutions, including:

- Bandsaw machines and equipment

- Bandsaw blades

- Installation and commissioning

- Training

- Servicing and parts

- Expert technical support and advice

Whatever your bandsaw related requirements, we can help. Whether you’d like to find out about which machines best suit your needs, require information about blade replacement, or would like to know about our servicing or training solutions, get in touch to find out more about how we can work with you.

For Expert Advice

Share this post: